If you have a business that requires sending your products to stores or customers, you’re surely familiar with product packaging. Cardboard is the preferred packaging material across various industries, and there are valid reasons behind this choice. What is cardboard? Who invented it? What are the benefits of using cardboard? Let’s explore everything beyond the box!

Cardboard – The Material Explained

What is cardboard?

Generally, “cardboard” refers to paper products that are thicker and heavier than standard paper. Today, cardboard material is commonly used in the packaging industry. Almost every product you see in retail stores is packed using a box made of cardboard. But not only that! You know those delicious bakery items, fashionable apparel, or luxury jewellery? They are also packed using boxes made of cardboard material.

The History of Cardboard

So, when was cardboard invented?

Speaking of history, the invention of cardboard originated in ancient China, where the first paper-like materials were created using the bark of the mulberry tree.

However, the cardboard we know today gained popularity in the 19th century. Thanks to Sir Malcolm Thornhill from England, the first commercially produced cardboard box was made in 1817. This invention offers a lightweight and durable alternative to wooden crates and barrels as product packaging.

What Is Cardboard Made of?

Typically, cardboard is made of paper fibres, which are obtained from wood pulp, then processed and formed into a layered structure to produce the sturdy, lightweight material. You might recognise the wavy shape of its distinctive fluting (or corrugation). This is often sandwiched between two layers of board.

What are the properties of cardboard?

Definitely, it remains a popular packaging material due to its ability to be easily cut, shaped, and printed on. Better yet, cardboard also provides good cushioning and protection for any product packed inside.

What Are the Different Types of Cardboard?

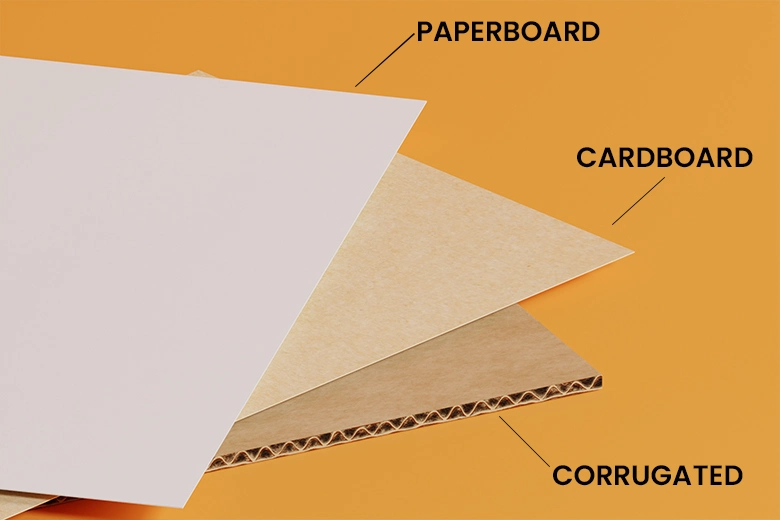

As of today, there are three primary types of cardboard used for packaging, each with its unique characteristics. The different types are mainly defined by their thickness, finish, and fluting.

What are they?

Paperboard

Known as solid cardboard, paperboard is a thicker and more rigid form of standard paper. It’s available in bleached and unbleached grades. This material type is primarily used for packaging lightweight products, such as cereal or small gifts.

Corrugated Cardboard

What is corrugated cardboard? Is it not the same as cardboard itself?

Well, as the name suggests, corrugated cardboard consists of a fluted, corrugated layer between two flat liners. This structure gives corrugated cardboard excellent strength and durability. In fact, one of the various uses of corrugated cardboard is as protective shipping boxes that offer extra cushioning, crush resistance, and structural stability.

Chipboard

Chipboard is also known as particleboard, a manufactured wood product made from wood particles or fibres. The fibres are then mixed with an adhesive under heat and pressure to form strong, rigid boards as a durable yet cost-effective option.

How Cardboard Is Made?

Now that we know the invention and types of cardboard, let’s find out how cardboard is made.

Here are the steps of its manufacturing process.

Pulping

The first step of the cardboard manufacturing process starts with pulping, where raw materials such as wood chips, recycled paper, and water are combined. The mixture will then be broken down into fibres.

Cleaning

Next, the pulp is cleaned and refined to remove impurities.

Bleaching

If you want to achieve a uniform white colour, the pulp may be bleached to remove any remaining colour.

Forming the Sheets

The next stage is spreading the pulp onto a moving mesh screen to form a continuous sheet. Then, the sheet will be pressed to remove excess water and passed through heated rollers to dry and bond the fibres together. The process yields paperboard or linerboard sheets, which are then wound into large rolls for further processing.

Corrugation

For the type of corrugated cardboard, the next step is corrugation, where linerboard sheets are passed through corrugating machines, creating the characteristic fluted pattern. These fluted sheets are then glued between two flat linerboards.

Cutting & Shaping

Using a die-cutting machine, the corrugated cardboard will be cut and shaped into any form of packaging and boxes.

Grades of Cardboard

In addition to the different types, there are several grades of cardboard. Grades here refer to the amount or percentage of recycled fibre present in cardboard.

- Kraft (K): It’s not been recycled before, as it’s made from virgin fibres.

- Test 2 (T2): It’s composed of certain parts made from recycled liner paper.

- Test 3 (T3): It’s made from 100% recycled fibres.

- Chip (C): Made from 100% waste-based liners.

- Bleached White (BW): It’s made from a bleached Kraft liner.

- White Top (WT): Made from white coated recycled fibres.

- Mottled Kraft (MK): A combination of virgin and recycled fibres.

- Oyster (OY): A mixture of virgin and recycled fibres.

- Semi-Chem (SC): It’s made with virgin fibres using a neutral sulfite semi-chemical process.

- Waste-based (WB): 100% recycled paper fibres are often used as fluting.

Do note that almost all grades of cardboard are recyclable. However, if it’s wax-coated or contaminated by food, oil, or other substances, it may not be recyclable.

The Benefits of Using Cardboard

Choosing and using cardboard can benefit businesses in many ways.

Optimum Product Protection

Cardboard offers high durability and excellent protection to safeguard products during transit. Moreover, its strength and cushioning properties help prevent damage, ensuring that your products reach their destination in optimal condition. Corrugated cardboard, in particular, is known for its ability to withstand rough handling.

Versatility

Its versatile nature means cardboard can be easily cut, folded, and shaped to create a wide range of products, from simple custom boxes to complex display stands.

Cost-Effective

If you’re looking for the most affordable packaging material in terms of production and transportation, cardboard is an ideal option. Its lightweight nature reduces shipping costs. Meanwhile, its availability and recyclability keep manufacturing costs low.

Recyclable and Reusable

Another great benefit of choosing cardboard is its recyclability. Cardboard is one of the most recycled materials globally, with a high recovery rate. Recycling cardboard reduces the need for virgin materials, conserves energy, and minimises waste. Additionally, many cardboard products are reusable, further extending their lifecycle and reducing environmental impact.

What’s Cardboard Used for?

With its amazing features and benefits, cardboard ends up being an ideal material for packaging and shipping products.

Here are some examples of how this material is applied across various industries.

Packaging and Shipping

Cardboard is widely used to package a variety of products, including food items, electronics, cosmetics, and apparel.

- Shipping boxes

Corrugated cardboard is the ideal choice for protecting products during transit, whether for small items or large appliances.

- E-commerce packaging

With the rise of online shopping, mailer boxes made of cardboard have become a significant shipping method.

- Internal packaging

Cardboard can be used as inserts or dividers inside the boxes to protect fragile items during shipping.

Other Applications

Besides being the trusted packaging material, cardboard is also used for some other applications, such as:

- Moving and storage

- Crafts and art

- Displays and signage

Is Cardboard Sustainable?

Yes, cardboard is sustainable.

Is cardboard biodegradable?

Yes, it is biodegradable, meaning it can break down naturally in the environment without leaving harmful residues. This property makes cardboard a more environmentally friendly option compared to plastic packaging. Hence, by choosing cardboard over plastic or other non-recyclable materials, your business can reduce its environmental footprint.

The Future of Cardboard

From its invention to the present day, cardboard has undergone significant innovations. Below are some advancements for the future of cardboard.

- Digital Printing

Digital printing technology is revolutionising the packaging industry, enabling high-quality, customisable prints on cardboard packaging. This innovation enhances the aesthetic appeal of cardboard products, helping brands create personalised packaging for their customers.

- Better Circular Economy

Cardboard has played a crucial role in creating a more circular economy, where materials are continually reused and recycled. Many businesses are increasingly adopting circular practices, such as designing their custom boxes for longevity and recyclability, and investing in recycling infrastructure.

Overall, we can confidently say that the future of cardboard is bright, and innovations are expected to continue growing.

Final Thoughts

Undoubtedly, cardboard is widely recognised as the preferred packaging material across various industries today. Almost every product you see in retail stores is packed using a box made of cardboard. Choosing cardboard offers numerous benefits, including optimal product protection, versatility, cost-effectiveness, and environmental friendliness.

Are you interested in having custom boxes made from cardboard? Custom Box Makers is an expert manufacturer you can rely on. Give us a call!

FAQs

What is cardboard?

Generally, “cardboard” refers to paper products that are thicker and heavier than standard paper. Today, cardboard material is commonly used in the packaging industry. Almost every product you see in retail stores is packed using a box made of cardboard.

What is cardboard made of?

Cardboard is made of paper fibres, which are obtained from wood pulp, then processed and formed into a layered structure to produce the sturdy, lightweight material.

How many types of cardboard are available?

There are three types of cardboard: Paperboard, Corrugated Cardboard, and Chipboard.

Why should we choose cardboard?

Choosing cardboard offers numerous benefits, including optimal product protection, versatility, cost-effectiveness, and environmental friendliness.

Is cardboard sustainable?

Yes, cardboard material is recyclable, biodegradable, and reusable, making it a sustainable and environmentally friendly option.